I decided that aluminum wasn't going to be rigid enough, so I chose 1/8 inch ABS sheeting instead. This summer when I fiberglassed our deck I came across this material at the fiberglass supply store in the form of offcuts - about 1 foot square, and 50 cents per sheet. I may even use ABS cement for the next one - this one was a trial run.

Getting started. One nice thing about ABS is that it cuts very nicely on a table saw.

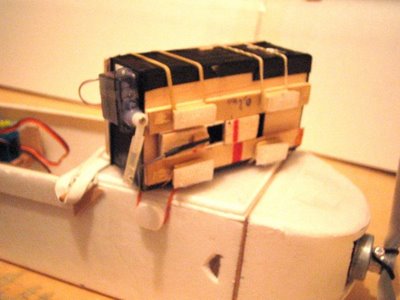

Adding hardware and the dividers that will eventually support the curved film guide. If you've followed my other cameras like the homemade folder you'll notice some familiar design elements.

Adding hardware and the dividers that will eventually support the curved film guide. If you've followed my other cameras like the homemade folder you'll notice some familiar design elements.

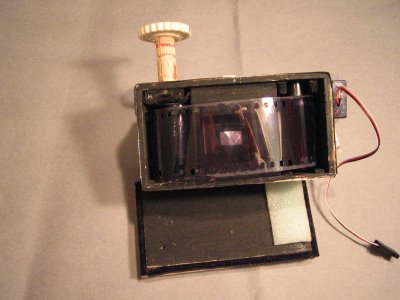

Adding the bottom plate. It swings down to allow loading of the spools. Hockey tape "bellows" keep things light-tight but allow for a flexible joint.

Adding the bottom plate. It swings down to allow loading of the spools. Hockey tape "bellows" keep things light-tight but allow for a flexible joint.

Aluminum (yes! it has aluminum!) braces hold the dividers steady. I would have used ABS cement but it smells - and it's darn cold outside right now...

Aluminum (yes! it has aluminum!) braces hold the dividers steady. I would have used ABS cement but it smells - and it's darn cold outside right now...

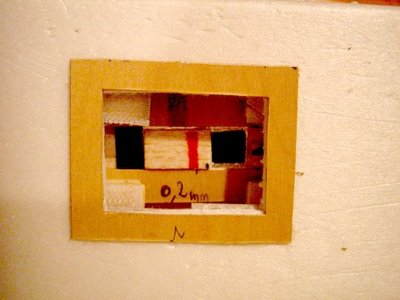

The film guide cut out and ready for installation.

Film guide installed. The tension of the flexed aluminum is enough to keep it in the desired curve. The "focal" radius is 85mm.

The back of the camera is simply a shallow ABS box that fits snugly over the camera and is lined with weatherstripping foam. The back has a red window for advancing film (for 6x18 with a centred window, start with "2" and then progress to 5, 8, et cetera).

The assembled camera, with sections of motorcycle innertube as industrial-strength elastics. All that remains is to install a pinhole and build a shutter (and get some 120 film!!) Stay tuned!